- ConstructionThin films, Wire Wound ceramic, Glass probes or Kapton surface

- Resistance valuePt50 to Pt10000

- Size and diameterStarting 0.8mm

- Accuracy DIN4370From Class B to 1/10

- Accuracy IEC 60751W0.3 to W0.03

Sensitive elements

Temperature sensor core, the sensitive elements proposed in this section are mainly platinum resistance temperature detectors (RTD), supplemented by thermistors. They cover a very wide temperature range from -200 °C to +850 °C.

Three types of RTD highlighted are:

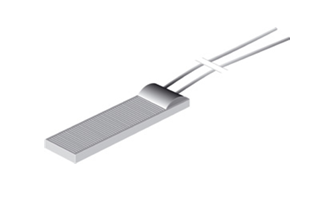

- Thin film elements

- Wire Wound in ceramic

- “Glass” probes

The Pt100 sensor is the most popular and also the most used in these three categories, although other resistance values are available such as Pt50, Pt200, Pt500, and Pt1000.

Thin film RTDs, also known as “thin film RTD” have become very popular due to their wafer processing which provides reliability, low cost and small size. They are covered with an insulator that gives them high resistance to thermal shocks and vibrations. Their flat profile is well suited for many industrial, medical, automotive, aerospace, cryogenic, and household applications.

Wound ceramic probes are among the most accurate. Although their cost is higher, they are indispensable in extreme and critical environments where stability, vibration resistance, and long-term reliability are essential. This product family is available in single and duplex versions.

Wound glass fiber platinum RTD elements are made by winding a pair of platinum wire around a glass core and then fusing the outside with glass. They are suitable for temperatures ranging from -200 °C to +450 °C and have the advantage of excellent resistance to vibrations and thermal shocks.